Content

В производстве щеток выбор правильного материала имеет решающее значение для эффективности продукта. Нейлоновая щетка PA66. , как высокоэффективное термопластичное синтетическое волокно, стали «универсальными» на рынке щетинок для кистей благодаря своим превосходным физическим свойствам.

Что такое нейлоновая щетка PA66?

Нейлоновая щетка PA66. (полиамид 66) образуются в результате конденсационной полимеризации адипиновой кислоты и гексаметилендиамина. По сравнению с PA6 (нейлоном 6), PA66 имеет более высокую температуру плавления, лучшую эластичность и более высокую стойкость к истиранию. Компактная молекулярная структура позволяет ему быстро возвращаться к исходной форме после сжатия, что делает его идеальным материалом для производства высококачественных промышленных и потребительских щеток.

Основные области применения нейлоновой щетки PA66

Благодаря своей уникальной механической прочности нейлоновая щетка PA66 имеет чрезвычайно широкий спектр применения: от повседневной жизни до высокоточного промышленного производства:

1. Промышленная очистка и обработка поверхности.

На промышленных автоматизированных производственных линиях нейлоновая щетка PA66 часто изготавливается из ленточных, роликовых или дисковых щеток.

- Удаление заусенцев с металла: Используется для удаления заусенцев с обработанных металлических деталей.

- Очистка конвейерной ленты: В пищевой промышленности и логистике его устойчивость к истиранию используется для очистки остатков конвейерной ленты.

- Полировка и шлифовка: С помощью абразивов щетина PA66 позволяет тонко полировать пластиковые или металлические поверхности.

2. Механические уплотнения и защита от пыли

Щетинки из нейлона PA66 обладают хорошей гибкостью и усталостной прочностью и обычно используются для герметизации различных механических зазоров.

- Герметизация дверей и окон: блокирует пыль, насекомых и холодный воздух.

- Защита от защемления лифта: Защитные щетки на краях юбки лифта обычно изготавливаются из прочного и безопасного материала PA66.

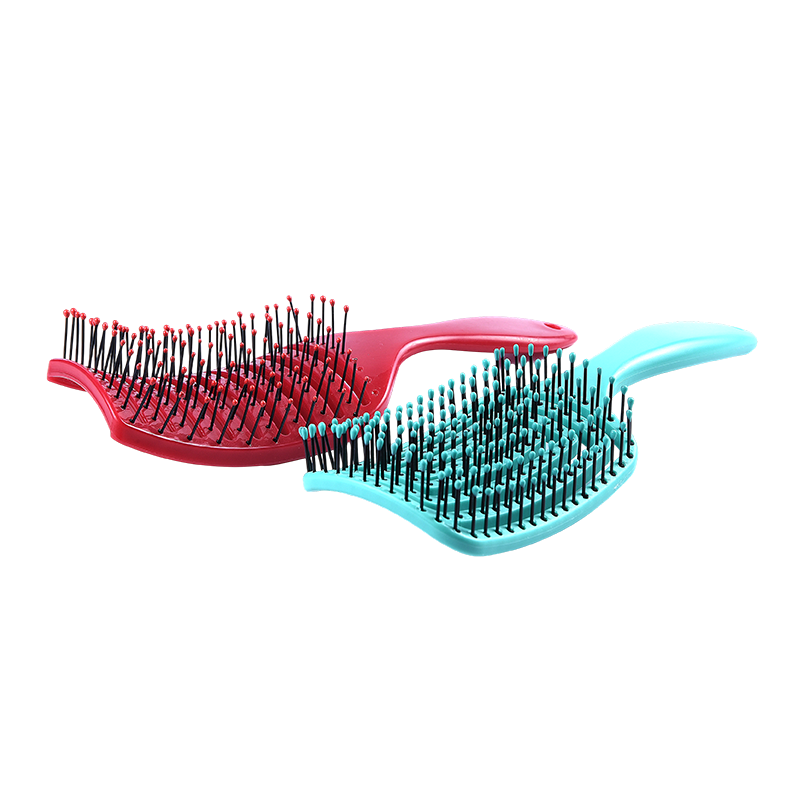

3. Средства личной гигиены

Во многих кистях, с которыми мы сталкиваемся в повседневной жизни, используется нейлоновая щетина PA66.

- Высококачественные расчески: щетина PA66 обладает хорошей термостойкостью и не деформируется при использовании фена.

- Насадки щетки для пылесоса: благодаря своей высокой устойчивости и антистатической обработке эффективно очищают ковры от глубоко укоренившейся грязи.

- Чистящие щетки: PA66, как и щетки для посуды и кастрюль, обладает превосходной устойчивостью к жиру и химикатам.

4. Применение в автомобильной промышленности

В автомобильной промышленности нейлоновая щетина PA66 используется для внутренней чистки, удаления пыли из моторного отсека и удаления пыли с поверхностей перед покраской.

Почему стоит выбрать нейлоновую щетину PA66?

- Чрезвычайно высокая стойкость к истиранию: Поддерживает очень низкий уровень износа даже при частом трении и высокоинтенсивных промышленных операциях, продлевая срок службы щеток.

- Отличная устойчивость и устойчивость к усталости: Быстро возвращается к исходной форме после изгиба и противостоит сплющиванию, сохраняя стабильную эффективность очистки.

- Отличная термостойкость: Более высокая температура плавления (~260°C) обеспечивает механическую прочность в условиях высоких температур.

- Хорошая химическая стойкость: Высокая устойчивость к жиру, смазочным материалам и органическим растворителям.

- Умеренная и жесткая твердость: Обеспечивает высокую очищающую способность, сохраняя при этом гибкость для защиты поверхностей.

Как определить высококачественную нейлоновую щетину PA66?

- Однородность цвета: Насыщенный цвет, отсутствие примесей.

- Стабильность флуоресценции: щетинки одинакового размера обеспечивают равномерное распределение давления на головку щетки.

- Тест на отскок: обратите внимание на скорость восстановления после нажатия на щетину вручную; PA66 должен показать мгновенный отскок.

Нейлоновая щетина PA66 благодаря своей высокой прочности, высокой стойкости к истиранию и превосходной термостабильности проникла во все аспекты нашего производства и повседневной жизни. Будь то промышленная уборка, требующая максимальной эффективности, или уход за домом, отдающий приоритет качеству жизни, PA66 — незаменимый высокоэффективный материал.

English

English русский

русский Türk

Türk